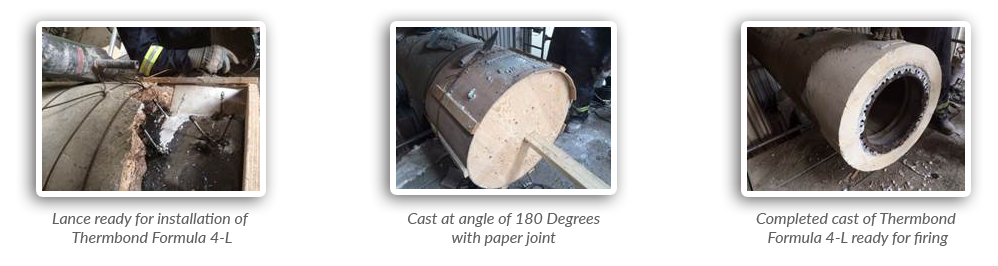

13 Jun Burner Lance Repair

Industry: Cement

Description of Equipment: Burner Lance

Problem: Refractory falls off and anchors oxidize from front to back requiring repeated lance tip repairs.

Solution: Install Thermbond Formula 4-L. This material will bond to existing refractory, resist thermal shock, and allow for a speedy installation with the possibility of rapid start-up as required.

Product Being Replaced: High Alumina Refractory

Savings Using Thermbond: Thermbond Formula 4-L will bond to the existing refractory allowing for patch repairs to the tip of the lance rather than a complete tear out and full relining of refractory. This saves the customer a significant amount of time and money in terms of maintenance as well allowing for quick start-up. Thermbond Formula 4-L will resist thermal shock, corrosion, and air velocity resulting in increased life of the refractory.

Products Applied: Thermbond Formula 4-L

Method of Installation: Poured into wooden form

Equipment Used: Paddle mixer, wooden forms, trowel to finish

Scope of Work: Remove old refractory until solid. Remove dust and vacuum surface. Weld new anchors, place the wooden forms, pour material, and startup as soon as possible.