02 May Thermblock Engineered Shapes – More than Double the Life Expectancy

Industry: Cement

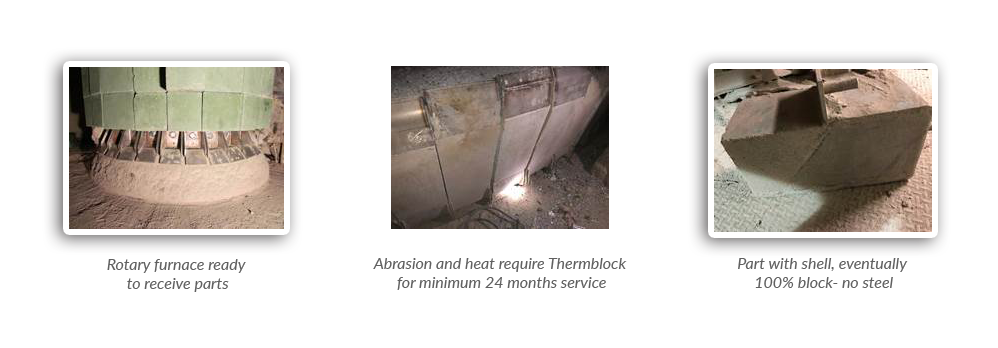

Description of Equipment: Rotary/ Eco Furnace

Problem: Furnace conditions result in high erosion and abrasion which causes residue to build up in the gaps and shift the blocks. Customer required a material that could resist these conditions.

Solution: Thermblock engineered blocks

Product Being Replaced and Repaired: Many different conventional products and precast shapes.

Thermbond Advantage: Previous cast parts required the use of a back plate. The back plates were removed from the furnace, transported to a contractor who reinstalled castable refractory. Once the refractory was cured and dried, the blocks were returned to the plant. Thermblock is robust enough that back plates are no longer needed. Previous material lasted 12-18 months, Thermblock is expected to last 2-3 years. Customer plans to use Thermblock in other strategic areas of the furnace.

Products Applied: Thermblock engineered blocks

Equipment Used: Crane operator and one or two people to secure in place. Blocks are then hand bolted with recommended torque.

Scope of Work: Removal of all hardware and back plates. Replace with one block and bolt to the furnace.

Installation Date: February 2019